We provide Ultrasonic Testing services using advanced non-destructive ultrasonic technology. Our services allow accurate evaluation of material condition and fluid flow without cutting, drilling, or interrupting operations. These methods are ideal for in-service inspection, condition assessment, and performance verification across industrial systems.

How Ultrasonic Thickness Testing Works?

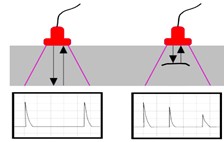

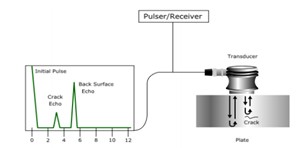

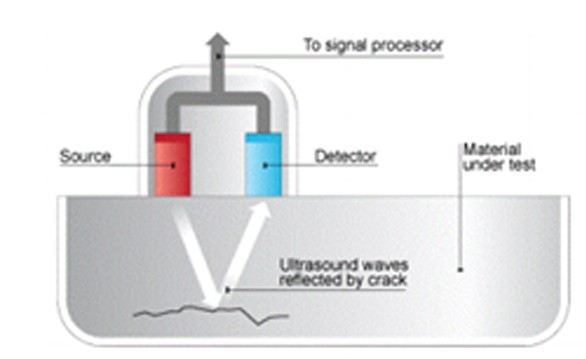

Ultrasonic Thickness Testing is a non-destructive method used to measure the remaining wall thickness of pipes, tanks, vessels, and structural components. High-frequency sound waves are transmitted through the material, and the time taken for the echo to return is used to calculate thickness with high accuracy

Ultrasonic Flow Meter Testing is a non-intrusive method used to measure liquid flow rates in closed pipelines. Clamp-on ultrasonic sensors transmit and receive sound signals across the pipe, allowing precise flow calculation without modifying the piping system

Both thickness and flow measurements are based on the transit time of ultrasonic waves. A couplant ensures proper transmission of sound from the probe to the surface. Measured time differences are converted into thickness or flow values using material and fluid properties.

Thickness measurement accuracy up to ±0.001 mm under optimal conditions Flow measurement accuracy dependent on pipe condition, fluid properties, and installation parameters Equipment is calibrated prior to testing Readings are recorded and documented for traceability

All ultrasonic thickness and flow measurements are carried out in accordance with applicable ASTM , ASME , Indian Standard guidelines, industry best practices, and client-specific requirements.